The Role of Technology in Streamlining EPR Compliance

Extended Producer Responsibility (EPR) regulations are reshaping how companies manage product lifecycle responsibilities, especially concerning waste management and recycling. As these regulations become more complex and widespread, businesses face significant challenges in ensuring compliance.

Fortunately, technology is emerging as a vital enabler, simplifying EPR reporting and tracking through automation, data integration, and advanced analytics. This article explores how digital solutions are transforming EPR compliance and the benefits they bring.

Understanding Extended Producer Responsibility

Extended Producer Responsibility is a policy approach that holds producers accountable for the environmental impacts of their products throughout the entire lifecycle. This includes design, manufacturing, distribution, and crucially, the post-consumer waste phase.

The goal is to incentivize producers to create more sustainable products and to ensure they contribute financially and operationally to waste collection and recycling efforts.

EPR regulations vary widely across regions and product categories, often requiring detailed reporting on product volumes, recycling targets, and fees. This complexity has made compliance a challenging task for many organizations, especially those operating internationally.

Challenges in Traditional EPR Compliance

Before the digital era, EPR compliance was largely a manual process. Companies relied on spreadsheets, emails, and disconnected systems to gather and report data. This approach posed several significant challenges.

Data collection was fragmented and prone to errors, as information had to be gathered from suppliers, manufacturers, and waste management partners. The regulatory landscape was constantly evolving, requiring manual monitoring and frequent adjustments to compliance processes.

Reporting deadlines were difficult to track, increasing the risk of late submissions and penalties. Additionally, the lack of real-time visibility made it hard for companies to proactively manage compliance risks or identify inefficiencies in their waste management practices.

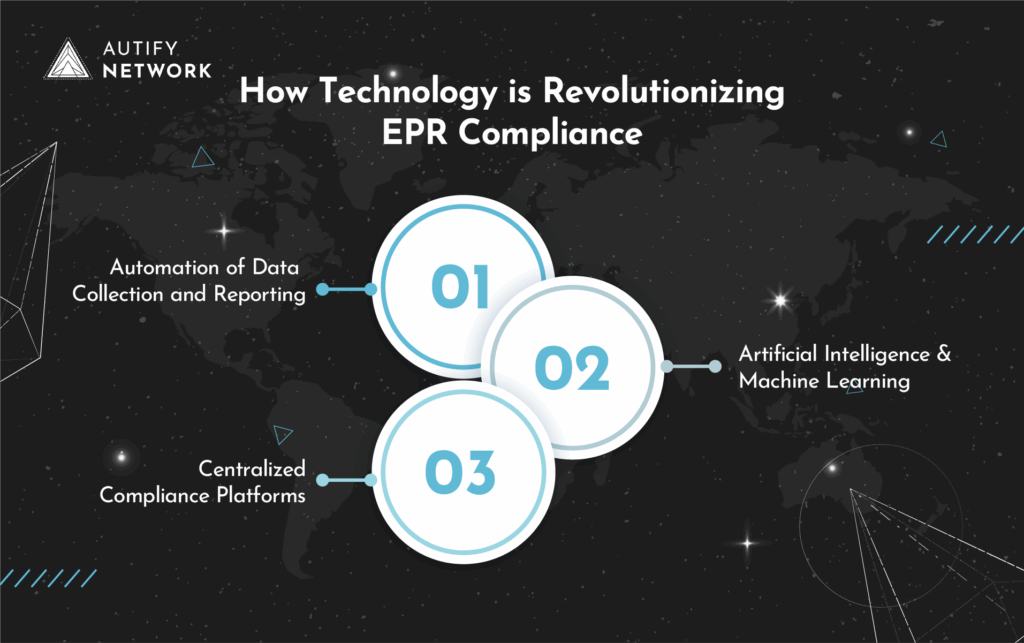

How Technology is Revolutionizing EPR Compliance

The integration of technology into EPR compliance workflows is fundamentally changing how businesses manage their obligations. Automation, artificial intelligence (AI), and integrated platforms are key drivers of this transformation.

1. Automation of Data Collection and Reporting

Digital platforms can automatically collect data from various internal systems such as ERP and supply chain management software. This eliminates the need for manual data entry, reducing errors and saving valuable time. Automated reporting tools generate compliance documents quickly and accurately, ensuring that companies meet regulatory deadlines without stress.

2. Artificial Intelligence and Machine Learning

AI technologies analyze complex datasets to uncover patterns and insights that humans might miss. Machine learning algorithms can track regulatory changes globally and adjust compliance workflows accordingly. AI also supports eco-design by recommending product or packaging modifications that reduce environmental impact and potentially lower EPR fees.

3. Centralized Compliance Platforms

Modern EPR compliance solutions provide centralized dashboards that consolidate data from multiple jurisdictions and product lines. This unified view enables companies to monitor their compliance status in real time, coordinate with suppliers and waste handlers, and prepare for audits with ease.

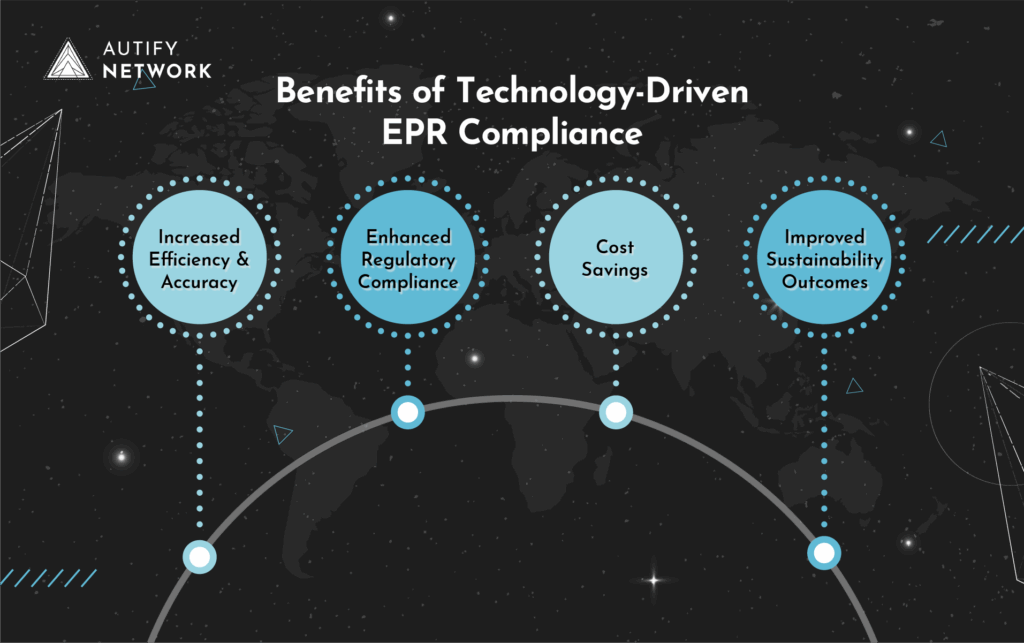

Benefits of Technology-Driven EPR Compliance

The adoption of digital solutions for EPR compliance offers numerous benefits that go beyond simply meeting legal requirements.

1. Increased Efficiency and Accuracy

Automation reduces the manual workload and minimizes human error, allowing compliance teams to focus on strategic tasks. Real-time data access enables faster report generation and submission, improving overall operational efficiency.

2. Enhanced Regulatory Compliance

Continuous monitoring of regulatory changes ensures that compliance efforts remain current. Automated alerts prevent missed deadlines, and accurate data builds trust with regulators, reducing the risk of fines or disputes.

3. Cost Savings

By streamlining compliance processes, companies reduce administrative costs and the risk of penalties. Data-driven insights also help optimize product design and waste management strategies, potentially lowering EPR fees.

4. Improved Sustainability Outcomes

Advanced analytics provide actionable insights that support eco-friendly product design and packaging. Transparent reporting and better waste tracking contribute to circular economy goals and enhance corporate social responsibility.

Real-World Applications of Technology in EPR Compliance

Several real-world examples underscore the transformative impact of technology on EPR compliance. A leading consumer electronics manufacturer, grappling with the complexities of product take-back and recycling, implemented an innovative AI-powered platform.

This strategic adoption automated the intricate processes of tracking returned products and calculating recycling rates with unprecedented accuracy. The tangible outcomes were remarkable, resulting in a significant 70% reduction in the man-hours required by their compliance team, freeing up valuable resources for more strategic initiatives.

Furthermore, the data insights gleaned from the AI-driven platform empowered the company to re-engineer their product packaging, leading to substantial reductions in plastic usage and a lighter environmental footprint.

In another compelling instance, a multinational packaging company addressed the challenges of managing EPR obligations across diverse geographical regions and numerous suppliers by adopting a centralized compliance dashboard. This integrated solution served as a single source of truth, seamlessly aggregating data from disparate sources and ensuring comprehensive oversight.

The implementation of this technological solution not only guaranteed 100% on-time reporting across all jurisdictions but also facilitated the adoption of eco-modulation strategies, leveraging AI-driven insights to optimize material choices and design for recyclability, ultimately resulting in tangible reductions in their overall EPR fees.

These success stories vividly illustrate the tangible benefits of embracing technology to navigate the complexities of EPR, driving both operational efficiencies and significant sustainability gains.

The trajectory of EPR compliance technology points towards an even more sophisticated and integrated future, driven by emerging innovations that promise to further enhance data accuracy, transparency, and predictive capabilities.

The Internet of Things (IoT) and the evolution of smart waste management systems are poised to revolutionize waste collection and recycling processes. The deployment of intelligent bins equipped with sensors will provide a continuous stream of real-time data on fill levels, waste composition, and collection efficiency, significantly improving traceability and the accuracy of reporting.

Blockchain technology holds immense potential for establishing immutable and transparent records of material flow and recycling activities, simplifying verification processes for all stakeholders and fostering greater trust among producers, regulators, and recyclers.

Furthermore, the application of predictive analytics and machine learning algorithms will empower companies to anticipate upcoming regulatory changes and potential compliance risks with greater foresight, enabling proactive adjustments to their strategies and minimizing potential disruptions.

Looking ahead, EPR compliance platforms will increasingly integrate with broader circular economy initiatives, creating interconnected ecosystems that facilitate efficient resource recovery, promote the design of products for circularity, and enable truly sustainable product lifecycle management, moving beyond mere compliance towards a holistic approach to resource stewardship.

Best Practices for Implementing Technology in EPR Compliance

To maximize the benefits of technology, companies should start by thoroughly assessing their current compliance processes and identifying pain points. Selecting a digital solution that integrates well with existing systems and offers automation, AI capabilities, and scalability is essential.

Training compliance teams and fostering collaboration with suppliers and waste management partners ensures accurate data sharing and smooth workflows. Finally, embedding continuous monitoring and improvement into the compliance strategy helps organizations stay ahead of regulatory changes and technological advancements.

Conclusion

Technology is revolutionizing Extended Producer Responsibility compliance by transforming it from a complex, manual task into an efficient, data-driven process. Automation, AI, and integrated platforms enable businesses to manage multi-jurisdictional regulations with greater accuracy, speed, and transparency. These digital solutions not only simplify compliance but also empower companies to advance sustainability goals, reduce costs, and build resilience in a rapidly evolving regulatory environment.

As EPR regulations continue to expand and evolve, embracing technology is no longer optional but essential for producers committed to environmental stewardship and long-term success. The future of EPR compliance is digital, and companies that adopt these innovations today will be best positioned to thrive tomorrow