Customer-Centric Supply Chains in the Age of Hyper Personalization

The modern consumer, empowered by digital technologies and a vast array of choices, no longer seeks one-size-fits-all products and services. Instead, they crave personalization – offerings tailored to their unique needs, preferences, and even aspirations. This shift in consumer demand is profoundly impacting every aspect of business, and perhaps nowhere is this impact felt more acutely than in the realm of supply chains.

The traditional linear, product-centric supply chain is evolving into a dynamic, customer-centric ecosystem, where responsiveness, flexibility, and data-driven insights are paramount. This transformation is not merely an operational adjustment; it represents a fundamental rethinking of how value is created and delivered in the age of personalization.

The Rise of the Personalized Consumer

The forces driving the demand for personalization are multifaceted. The proliferation of e-commerce and social media has exposed consumers to a global marketplace, fostering a desire for unique and differentiated products.

Simultaneously, advancements in data analytics and artificial intelligence have enabled businesses to understand individual customer needs at an unprecedented level. Consumers now expect companies to leverage this understanding to offer products and experiences that resonate with their specific requirements.

This expectation extends beyond the product itself to encompass the entire customer journey, including sourcing, manufacturing, fulfillment, and after-sales service.

Furthermore, the concept of the “experience economy” has gained traction. Consumers are increasingly valuing experiences over mere possessions. Personalized products and services contribute significantly to a more engaging and satisfying customer experience, fostering loyalty and advocacy.

\Whether it’s a customized pair of sneakers, a subscription box tailored to individual preferences, or a personalized recommendation engine, consumers are willing to pay a premium for offerings that feel specifically designed for them.

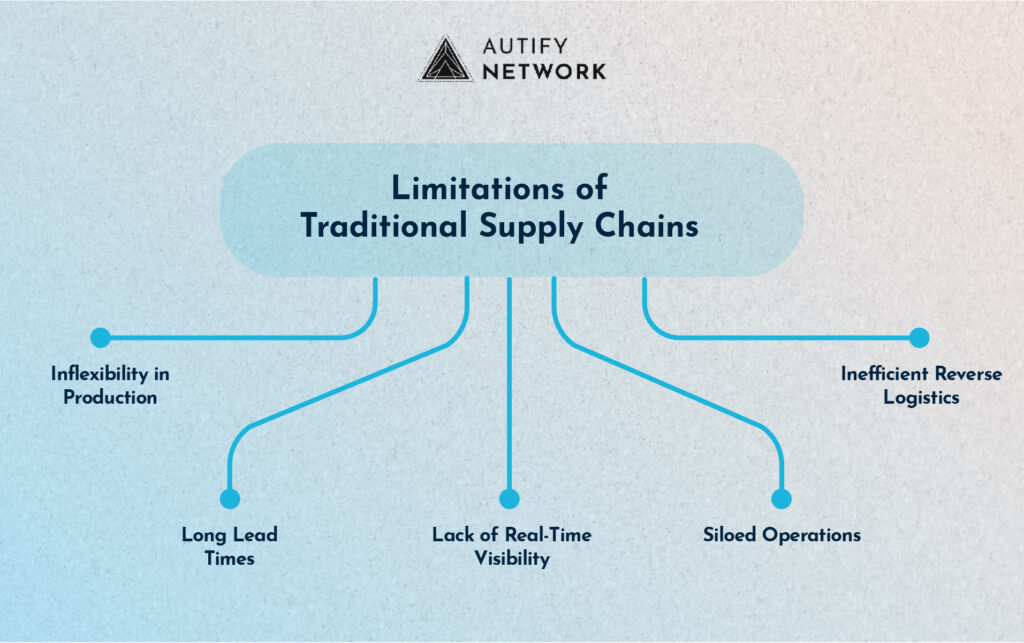

The Limitations of Traditional Supply Chains

Traditional supply chains, built on principles of mass production and efficiency, often struggle to accommodate the nuances of personalization. These linear models are typically optimized for standardized products, long lead times, and economies of scale.

The inherent inflexibility and lack of real-time visibility make it challenging to respond effectively to fluctuating individual demands and the need for product variations.

Key limitations of traditional supply chains in the context of personalization include:

- Inflexibility in Production: Mass production systems are designed for high volumes of identical products. Adapting production lines for small batches or customized items can be costly and time-consuming.

- Long Lead Times: Traditional forecasting methods, based on historical aggregate demand, struggle to predict individual preferences. This can lead to inaccurate inventory levels and delays in fulfilling personalized orders.

- Lack of Real-Time Visibility: Limited transparency across the supply chain makes it difficult to track individual orders, manage customized components, and respond proactively to potential disruptions.

- Siloed Operations: Functional silos within the organization can hinder the flow of information between customer-facing teams and the supply chain, preventing a holistic understanding of individual needs.

- Inefficient Reverse Logistics: Handling returns of personalized items can be complex and costly, as these products may not be easily resold or reintegrated into standard inventory.

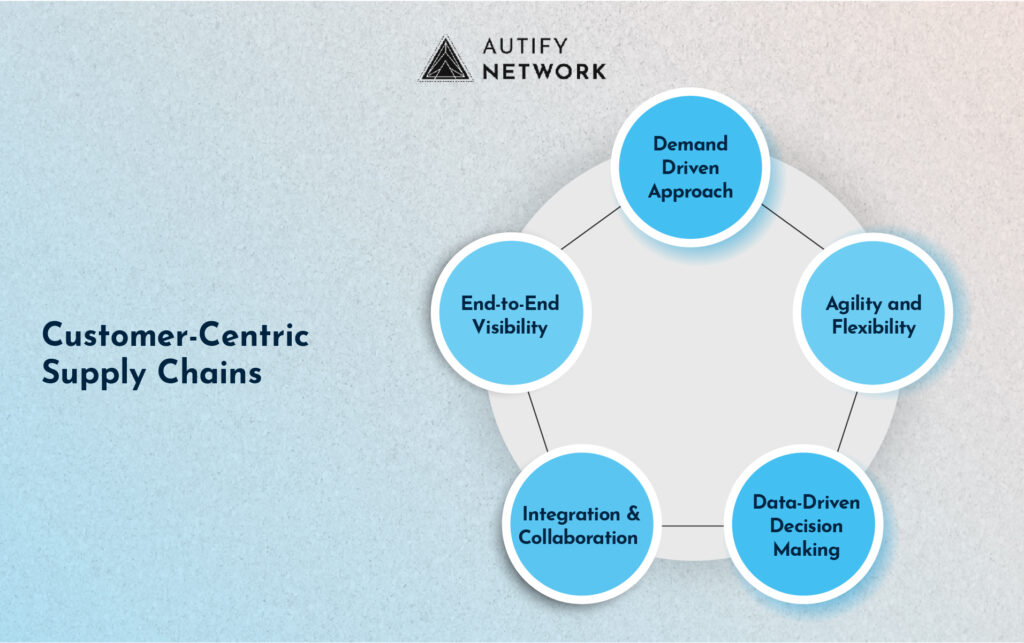

The Emergence of Customer-Centric Supply Chains

To thrive in the age of personalization, businesses are transforming their supply chains into customer-centric ecosystems. This involves a fundamental shift in focus from pushing products to meeting individual customer needs proactively. Key characteristics of customer-centric supply chains include:

- Demand-Driven Approach: Instead of relying solely on historical forecasts, these supply chains leverage real-time data and predictive analytics to anticipate individual customer demand and personalize offerings accordingly.

- Agility and Flexibility: Customer-centric supply chains are designed to be highly adaptable, capable of handling product variations, small batch sizes, and rapid changes in demand. This often involves modular production systems, flexible manufacturing technologies, and agile sourcing strategies.

- End-to-End Visibility: Enhanced transparency across the entire supply chain, from raw material sourcing to final delivery, provides real-time insights into inventory levels, order status, and potential disruptions, enabling proactive decision-making and personalized communication with customers.

- Integration and Collaboration: Breaking down internal silos and fostering seamless collaboration between different functions, including marketing, sales, product development, and operations, is crucial for understanding and responding to individual customer needs effectively. Collaboration extends beyond internal teams to encompass external partners, such as suppliers and logistics providers.

- Data-Driven Decision-Making: Customer-centric supply chains are powered by data. Advanced analytics tools are used to analyze customer data, identify patterns, predict future demand, and optimize every aspect of the supply chain for personalization.

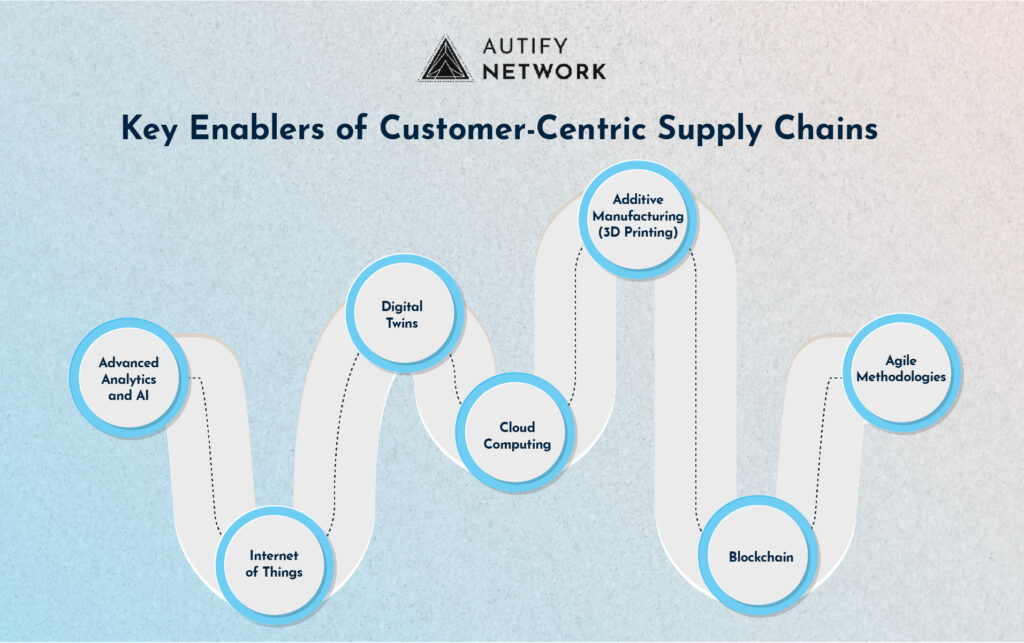

Key Enablers of Customer-Centric Supply Chains

Several technological and strategic enablers are facilitating the transition towards customer-centric supply chains in the age of personalization:

- Advanced Analytics and Artificial Intelligence (AI): AI-powered tools can analyze vast amounts of customer data to identify individual preferences, predict future demand for personalized products, optimize inventory levels, and personalize recommendations. Machine learning algorithms can continuously refine these predictions and optimize supply chain operations in real-time.

- Digital Twins: Creating digital representations of the physical supply chain allows businesses to simulate different scenarios, test the impact of personalization strategies, and optimize processes before implementing them in the real world. This virtual environment facilitates experimentation and risk mitigation.

- Internet of Things (IoT) and Sensor Technologies: Connected devices and sensors throughout the supply chain provide real-time data on inventory levels, product conditions, and location, enhancing visibility and enabling proactive responses to potential issues. This data can also be used to personalize delivery options and provide customers with real-time updates.

- Cloud Computing: Cloud-based platforms provide the scalability and flexibility required to manage the vast amounts of data generated in a personalized supply chain. They also facilitate collaboration and data sharing among different stakeholders.

- Additive Manufacturing (3D Printing): 3D printing technologies enable on-demand production of customized products, reducing lead times and eliminating the need for large-scale production runs of standardized items. This is particularly valuable for highly personalized products with low demand volumes.

- Blockchain Technology: Blockchain can enhance transparency and traceability in the supply chain, providing customers with information about the origin and journey of their personalized products. This can build trust and enhance the overall customer experience.

- Modular and Flexible Manufacturing: Investing in modular production systems and flexible automation technologies allows manufacturers to adapt quickly to changes in product specifications and produce small batches of customized items efficiently.

- Agile Methodologies: Adopting agile principles in supply chain management enables faster iteration, improved responsiveness to changing customer needs, and enhanced collaboration across teams.

Challenges in Implementing Customer-Centric Supply Chains

Implementing customer-centric supply chains in today’s era of personalization, while offering substantial advantages, presents a complex array of challenges that organizations must navigate. The inherent need to cater to individual customer preferences amplifies the complexity of product variations, order fulfillment, and logistical operations.

Furthermore, the reliance on extensive sensitive customer data necessitates the deployment of sophisticated data management systems coupled with unwavering security measures to safeguard privacy. The adoption of new technologies and the adaptation of existing production processes to accommodate this level of customization can also lead to significant cost implications, requiring businesses to carefully evaluate these investments against the anticipated gains in customer loyalty and revenue.

Addressing potential talent and skill gaps within the workforce, particularly in areas like data analytics and agile methodologies, is also paramount. The integration of often outdated legacy systems with novel customer-centric processes can prove to be a time-consuming and expensive hurdle.

Moreover, striking a delicate balance between offering highly personalized products and maintaining operational efficiency to ensure profitability remains a critical challenge. Finally, the complexities associated with managing returns of uniquely personalized goods necessitate the development of robust and effective reverse logistics strategies.

The Future of Customer-Centric Supply Chains

The evolution towards truly customer-centric supply chains in this era of personalization is a continuous process, with the future poised to witness an even more profound assimilation of digital technologies, a more nuanced comprehension of individual customer desires through sophisticated analytics, and the emergence of increasingly flexible and adaptive supply chain frameworks.

Several key trends are set to define this future landscape. Hyper-personalization will transcend basic customization, delivering truly unique and individualized products and experiences derived from real-time data and contextual insights.

Predictive and proactive supply chains, powered by AI and machine learning, will anticipate individual customer needs before they are explicitly voiced, enabling preemptive inventory management and tailored recommendations. Autonomous supply chains will see greater reliance on automation and AI-driven decision-making to streamline supply chain processes, minimizing human involvement and enhancing both efficiency and responsiveness.

The integration of circular supply chain principles will become more prevalent, focusing on minimizing waste and extending the lifespan of personalized goods, aligning with growing consumer consciousness regarding sustainability.

The adoption of Direct-to-Consumer (D2C) models will likely expand as brands seek greater command over the customer journey and aim to gather first-party data to fuel their personalization strategies, necessitating the development of in-house agile and customer-focused supply chain capabilities.

Finally, personalized delivery experiences, offering customers greater agency over delivery options, including timing, location, and even delivery personnel, will become increasingly important in enhancing convenience and overall satisfaction.

Conclusion

The age of personalization has ushered in a new era for supply chain management. The traditional, product-centric model is no longer sufficient to meet the demands of empowered consumers who expect tailored products and seamless experiences. The transition towards customer-centric supply chains, characterized by agility, visibility, data-driven insights, and a deep understanding of individual needs, is not merely an operational imperative but a strategic necessity for businesses seeking to thrive in this evolving landscape.

While challenges exist in implementation, the potential benefits of enhanced customer loyalty, increased revenue, and a stronger competitive advantage make the journey towards customer-centricity a worthwhile and inevitable evolution for the modern supply chain. By embracing technological advancements, fostering collaboration, and prioritizing the individual customer, businesses can transform their supply chains from cost centers into strategic enablers of personalized value creation.