The Future of EPR: Emerging Trends and Predictions

In the quiet revolution of global sustainability, Extended Producer Responsibility (EPR) has emerged as one of the most powerful and transformative forces. What began decades ago as a seemingly simple policy tool, designed to shift the financial and operational burden of managing post-consumer waste from municipalities to the producers themselves, has now blossomed into a dynamic global movement.

Today, EPR is driving profound innovation, fostering unprecedented transparency, and embedding genuine accountability across an ever-widening array of industries.

But as EPR continues its rapid evolution, what will the next decade truly look like? How will policies adapt to the accelerating pace of technological change and the escalating urgency of our climate crisis? The era of incremental adjustments is giving way to a period of radical reimagining.

This piece will delve into the emerging trends, critical challenges, and immense strategic opportunities that are poised to define the future of EPR, painting a picture of a world where sustainability is not just a buzzword, but an intrinsic component of every product’s journey.

EPR’s Expanding Reach: Beyond Packaging and Electronics

For many years, the conversation around EPR was largely confined to specific, high-visibility waste streams: packaging, electronics (WEEE), and batteries. These were the “usual suspects” – products with clear environmental impacts and established collection infrastructures. However, this narrow focus is rapidly dissolving.

Governments and regulatory bodies worldwide are now aggressively expanding the scope of EPR to encompass a far more diverse and complex array of goods, ranging from textiles and mattresses to furniture, construction materials, tires, lubricants, and even fast-moving consumer goods like cosmetics.

Why this profound expansion? The answer is multifaceted and deeply rooted in our current environmental reality:

- Growing Complexity of Waste Streams: Modern consumption patterns generate incredibly varied and often hazardous waste. As global populations grow and consumption increases, so too does the volume and complexity of discarded products. Landfills are reaching capacity, and existing recycling infrastructure struggles with mixed materials and novel product compositions.

- Urgency of Climate Action: Beyond simple waste management, EPR is increasingly recognized as a potent tool for reducing greenhouse gas emissions. By incentivizing recycling and reuse, it reduces the demand for energy-intensive virgin materials and diverts organic or carbon-intensive waste from landfills where it could produce methane.

- Unaddressed Environmental Pressures: Specific sectors, previously overlooked by EPR, are revealing their substantial environmental footprints. In Europe, textiles, for instance, are now the fourth largest source of environmental pressure after food, housing, and transport – a shocking statistic that highlights the need for systemic change in the fashion industry. Similarly, the immense volume of furniture and construction waste filling up landfills demands targeted intervention.

Pioneering nations like France have already set a precedent, implementing comprehensive EPR schemes for over 30 distinct product categories, from sports and leisure items to toys and DIY tools. This breadth reflects a proactive, holistic approach to product lifecycle management.

Concurrently, the EU’s ambitious Green Deal is pushing for even broader, more harmonized coverage across its member states, envisioning a truly circular economy. In emerging economies like India, EPR is being aggressively extended to plastics, e-waste, and batteries, crucially backed by robust digital tracking systems to ensure compliance and traceability.

The message emanating from this global policy evolution is unequivocally clear: EPR is swiftly becoming a universal standard, transcending its former status as a regional experiment. This broad expansion means that virtually no industry will remain untouched by the imperative of producer responsibility, forcing a fundamental rethink of product stewardship across the entire global economy.

From End-of-Life Management to Design: The Circular Shift

Perhaps one of the most exciting and transformative shifts within EPR is its evolution from merely managing waste at the end of a product’s life to profoundly influencing how products are designed from their very inception.

This represents a pivotal transition from a linear “take-make-dispose” mindset to a truly circular economy paradigm. The fundamental question for producers is no longer just “How do we responsibly recycle this once it’s discarded?” but rather, “How do we design this product so it can be easily reused, repaired, refurbished, or efficiently recycled into high-quality secondary raw materials in the first place?”

This critical shift is being powerfully catalyzed by eco-modulated fees. Traditionally, EPR fees were often a flat rate based on the volume or weight of products placed on the market.

Now, a growing number of EPR schemes are implementing differentiated fees: companies that make products easier to recycle or reuse, that use recycled content, or avoid hazardous substances, pay lower fees.

Conversely, those that design products with complex, non-separable materials, include problematic chemicals, or promote single-use models face significantly higher charges. The result is a direct, undeniable financial incentive: suddenly, it demonstrably pays to be sustainable. This mechanism effectively leverages market forces to drive greener design choices.

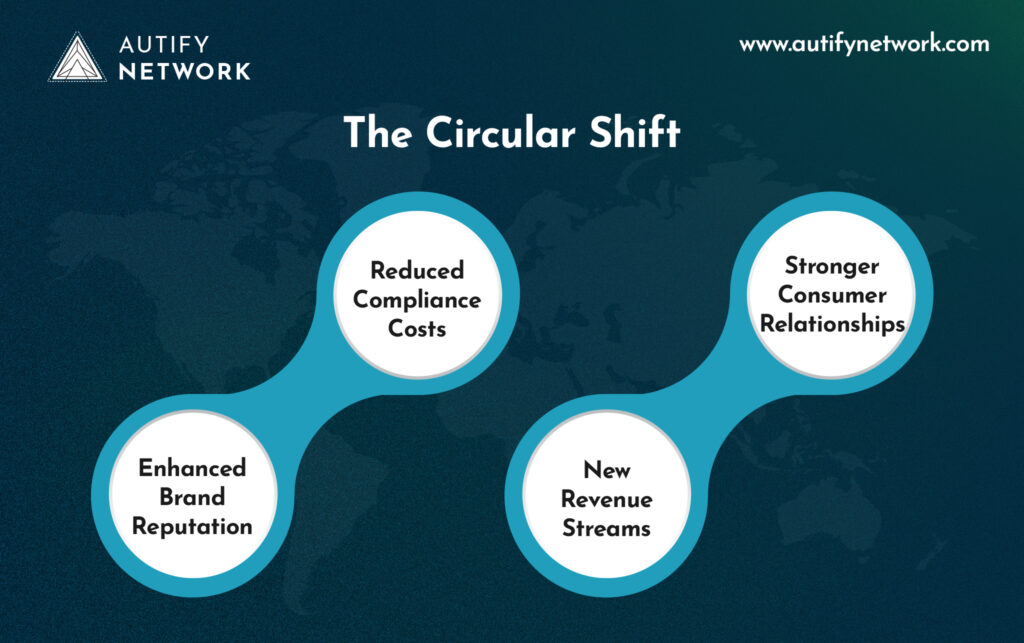

Brands that proactively embrace this circular mindset are experiencing tangible benefits that extend far beyond mere compliance:

- Reduced Compliance Costs: By optimizing product design for circularity, companies can reduce the eco-modulated fees they pay, turning a regulatory cost into a strategic advantage.

- Stronger Consumer Relationships: A growing segment of consumers, particularly younger generations, actively seeks out and rewards brands that demonstrate genuine environmental responsibility. Embracing circularity fosters trust and loyalty among this crucial demographic.

- New Revenue Streams: The circular economy opens up diverse new business models. Companies are unlocking new revenue opportunities through repair services, refurbishment programs, product-as-a-service models, and the resale of recovered parts or materials. This transforms waste from a cost center into a value generator.

- Enhanced Brand Reputation: Proactive engagement with circular design principles positions brands as leaders in sustainability, differentiating them from competitors and attracting talent.

This paradigm shift means that designers, engineers, and product development teams are now sitting at the forefront of EPR strategy, not just the compliance department. Their choices at the drawing board directly impact the financial bottom line and the environmental footprint of the entire product lifecycle.

Digitalization: The Backbone of Modern EPR

If there’s one overarching trend that is transforming every facet of EPR more profoundly than any other, it is the pervasive adoption of digitalization. The era of manual tracking, fragmented data, and cumbersome paper records is rapidly fading, giving way to an interconnected, data-rich ecosystem.

Today, cutting-edge technologies like blockchain, the Internet of Things (IoT), and Artificial Intelligence (AI) are making it possible to trace products through every stage of their lifecycle with unprecedented precision and transparency.

At the heart of this digital revolution are Digital Product Passports (DPPs), which are transforming transparency and accountability across industries like apparel, electronics, and plastics.

By simply scanning a QR code or NFC tag on products such as jackets, smartphones, or electric vehicle batteries, consumers gain instant access to a wealth of information—including material origins, environmental footprint, recycling instructions, repair methods, and even local repair services.

This empowers individuals to make informed choices and actively participate in the circular economy. For recyclers and remanufacturers, DPPs provide essential data on material composition, hazardous substances, disassembly procedures, and optimal recycling pathways, enabling more efficient processing and higher-quality material recovery.

Meanwhile, regulators and producers benefit from verifiable, real-time data for compliance reporting, validation of recycled content claims, and end-to-end supply chain accountability, making DPPs a cornerstone of sustainable and transparent product lifecycles

On the backend, sophisticated digital platforms are fundamentally streamlining EPR. These platforms, often powered by AI, are automating compliance reporting, integrating data from diverse sources (such as sales data, import records, and recycling certificates), and providing real-time dashboards for producers to monitor their obligations.

Simultaneously, they are helping Producer Responsibility Organizations (PROs) – the entities that manage EPR schemes on behalf of producers – to coordinate collection, sorting, and recycling operations more effectively across vast geographic areas.

The result is a significant reduction in administrative hassle, vastly improved data quality and availability, and a far more efficient and circular flow of materials across the entire value chain. This digital backbone is essential for managing the increasing complexity of future EPR schemes.

The Challenges: Complexity, Infrastructure, and Equity

Of course, the journey towards this advanced and comprehensive future of EPR is not without its significant hurdles. While the promise is immense, several critical challenges must be addressed to ensure its successful and equitable implementation.

1. Regulatory Complexity and Lack of Harmonization

As EPR expands globally, so does the administrative burden for multinational producers. Many companies currently face a fragmented patchwork of regulations, with each jurisdiction boasting its own unique definitions of products, specific reporting requirements, varying target methodologies, and distinct fee structures.

This lack of harmonization creates enormous inefficiencies, increases compliance costs, and can deter even well-intentioned businesses, especially those operating in multiple international markets. Streamlining and creating greater alignment across national and regional EPR frameworks will be paramount to unlocking truly global circularity.

2. Infrastructure Gaps

Even the most meticulously crafted EPR policies can falter without the necessary physical infrastructure. In many regions, particularly developing countries, formal waste management systems are underdeveloped, often lacking robust collection networks, sophisticated sorting facilities, and advanced recycling technologies.

Significant investment is required to bridge these gaps and build the capacity to handle diverse and complex waste streams. This includes not just physical plants but also the logistics and data infrastructure needed to support modern EPR.

3. The Human Factor and Social Equity

In many developing countries, the informal waste sector – comprised of countless waste pickers and recyclers – plays an incredibly vital role in material recovery, often collecting the majority of recyclables. Integrating these informal workers into formal EPR frameworks is not merely an operational challenge but a critical social equity and justice imperative.

Future EPR models must prioritize fair labor practices, safe working conditions, and opportunities for these individuals to transition into formal employment within the evolving circular economy, ensuring that the benefits of EPR are distributed equitably and do not inadvertently marginalize vulnerable communities.

EPR as a Strategic Opportunity

Despite these inherent complexities and challenges, EPR offers enormous strategic opportunities for forward-thinking businesses. It’s no longer simply about regulatory compliance or mitigating environmental harm; it’s about proactively building resilience, driving innovation, strengthening brand reputation, and unlocking new avenues for value creation.

Companies that move beyond a reactive “check-the-box” mentality and proactively engage with EPR can reap significant, multifaceted rewards:

- Reduce Regulatory and Reputational Risks: By anticipating policy changes and exceeding minimum requirements, companies can stay ahead of the curve, avoid penalties, and protect their brand image from accusations of greenwashing.

- Improve Operational Efficiency: Embracing circular design principles can lead to reduced material costs, optimized manufacturing processes, and more efficient reverse logistics, directly impacting the bottom line.

- Build Consumer Loyalty: In an era of heightened environmental awareness, consumers are increasingly choosing brands that align with their values. Involving customers in take-back, repair, and recycling programs fosters trust, creates a sense of shared responsibility, and builds a stronger emotional connection to the brand.

- Unlock Innovation: The necessity to meet EPR targets often spurs internal R&D for new materials, product designs, and business models that are inherently more sustainable, leading to competitive differentiation.

- Attract and Retain Talent: Younger generations, in particular, seek employers with strong sustainability credentials. A robust EPR strategy can be a powerful tool for talent acquisition and retention.

Crucially, collaboration is the golden thread that will weave together the most successful EPR strategies of the future. The immense scale and interconnectedness of global supply chains demand a collective effort.

The most impactful EPR initiatives will be those that bring together a diverse array of stakeholders: producers, governments, recyclers, technology providers, civil society organizations, and even consumers.

This collaboration will be vital for harmonizing standards, investing in essential infrastructure, sharing best practices, and collectively driving systemic change.

Predictions: What Will EPR Look Like by 2030?

Looking ahead, several definitive trends are likely to define the landscape of Extended Producer Responsibility by the end of this decade:

1. EPR Becomes the Global Norm

By 2030, over 100 countries will have comprehensive EPR laws in place, covering a dramatically wider range of product categories than today. This widespread adoption will make EPR an almost universal prerequisite for market access.

Simultaneously, significant progress will have been made in policy harmonization across major economic blocs and even globally, substantially reducing the current compliance complexity for multinational brands and facilitating more efficient cross-border material flows.

2. Eco-Modulated Fees Drive Relentless Innovation

The system of eco-modulated fees will become the dominant financial mechanism in EPR schemes. These fees will be meticulously linked to a product’s actual environmental performance, pushing companies to invest heavily in circular design, material innovation, and sustainable manufacturing processes.

This financial pressure will accelerate the shift towards products that are inherently durable, repairable, reusable, and optimized for high-quality recycling, transforming product development from a linear to a circular process.

3. Digitalization is Ubiquitous and Integrated

Real-time tracking, digital product passports (DPPs), and automated compliance reporting will become standard operating procedure across all major EPR schemes.

Blockchain, IoT, and AI will not just be supplementary tools but foundational technologies, driving unprecedented levels of transparency, efficiency, and accountability throughout the product lifecycle. This will allow for granular data analysis, predictive insights for waste streams, and seamless communication between all stakeholders.

4. Consumers Take an Active Lead

The role of consumers will evolve from passive disposers to active participants in the circular economy. Brands will launch a significantly wider array of engaging take-back, repair, refill, and recycling programs, making sustainable choices convenient and rewarding.

Consumers, empowered by transparent information provided through DPPs and increased environmental literacy, will actively demand more sustainable products and engage enthusiastically with circularity initiatives, wielding their purchasing power to reward responsible brands.

5. Social Inclusion Becomes Central to EPR Frameworks

Future EPR frameworks will place a strong, explicit emphasis on social equity. Policies will prioritize fair labor practices, safe working conditions, and the systematic integration of informal waste workers into formal EPR collection and processing systems.

This ensures that the environmental benefits of EPR are achieved hand-in-hand with social justice, providing stable livelihoods and dignified work opportunities for vulnerable communities.

6. Full Integration with Climate and ESG Goals

EPR will no longer be a standalone environmental policy but will be fully aligned and deeply integrated with companies’ broader net-zero commitments, climate strategies, and ESG (Environmental, Social, and Governance) reporting frameworks.

EPR performance will become a key lever for companies to meet their climate targets, demonstrate genuine sustainability leadership, and attract ESG-conscious investors and talent. It will be seen as a tangible measure of a company’s commitment to planetary health and responsible business practices.

Case in Point: EPR in Action

To understand the tangible impact of these trends, it’s useful to examine how different regions are pioneering the future of Extended Producer Responsibility (EPR). France stands out as a global leader, with its EPR system encompassing over 30 product categories and demonstrating a strong commitment to comprehensive producer responsibility.

The country’s robust eco-modulation framework actively incentivizes sustainable product design, while ongoing investment in consumer education drives high participation rates and improved sorting practices. In India, EPR for plastics and e-waste is rapidly evolving, marked by the adoption of digital tracking systems and ambitious recycling targets.

A significant focus is placed on formalizing and integrating the vast informal waste worker sector, aiming for a socially equitable transition to a circular economy. Meanwhile, the European Union is at the forefront of implementing Digital Product Passports for electronics, textiles, and batteries, establishing a powerful framework to support repair, reuse, and high-quality recycling across its diverse member states.

This initiative promises unprecedented transparency and empowers both consumers and recyclers to participate more effectively in sustainable practices.

How Can Businesses Prepare?

Ready to future-proof your EPR strategy and transform it into a competitive advantage? Here’s how forward-thinking businesses can get started and thrive in the evolving EPR landscape:

1. Conduct a Comprehensive Portfolio Audit: Identify all current and anticipated EPR regulations affecting your existing and future product lines. Understand the nuances of each regional policy.

2. Invest Heavily in Circular Design: Make “design for circularity” a core principle of your product development. Prioritize materials that are reusable, repairable, and easily recyclable. Consider product-as-a-service models or refill systems.

3. Embrace Digital Transformation: Adopt cutting-edge digital tools for end-to-end tracking, automated reporting, and the implementation of digital product passports. Leverage AI for data analysis and predictive insights.

4. Foster Robust Stakeholder Engagement: Build strong, collaborative relationships across your entire value chain – from upstream suppliers to downstream recyclers, waste management companies, and logistics providers. Actively engage with consumers through take-back and reuse programs.

5. Stay Ahead of Policy Changes: Dedicate resources to tracking evolving EPR legislation globally. Participate actively in industry associations and policy dialogues to help shape future regulations rather than merely reacting to them.

6. Champion Social Responsibility: Integrate social equity into your EPR strategy by supporting fair labor practices and, where applicable, collaborating with initiatives that integrate informal waste workers into formal collection and recycling systems.

Conclusion: A Systemic Shift Towards a Circular Future

The future of EPR is undeniably bright, complex, and teeming with potential. As EPR expands its reach, digitizes its operations, and aligns ever more closely with pressing climate and social goals, it will cement its position as a defining force for sustainable business and a truly circular global economy.

For companies, the challenge is clear: it’s time to move decisively beyond mere compliance and wholeheartedly embrace EPR as a strategic opportunity to innovate, collaborate, and lead the way towards a more responsible future. For governments, civil society, and consumers, EPR offers a tangible, powerful path to significantly reduce waste, conserve precious resources, mitigate climate change, and ultimately build a more just, equitable, and sustainable world for generations to come. The grand transformation of EPR is not just an aspiration; it is the imperative of our time.